Single-Stage vs. Multistage Pumps: How to Choose the Best One

Centrifugal pumps come in various types, but the two most commonly used are single-stage pumps and multistage pumps. While both serve a similar purpose, differences in the number of impellers and how they work make each suitable for different applications. Let’s explore the key differences between these two types of pumps so you can choose the right one for your needs.

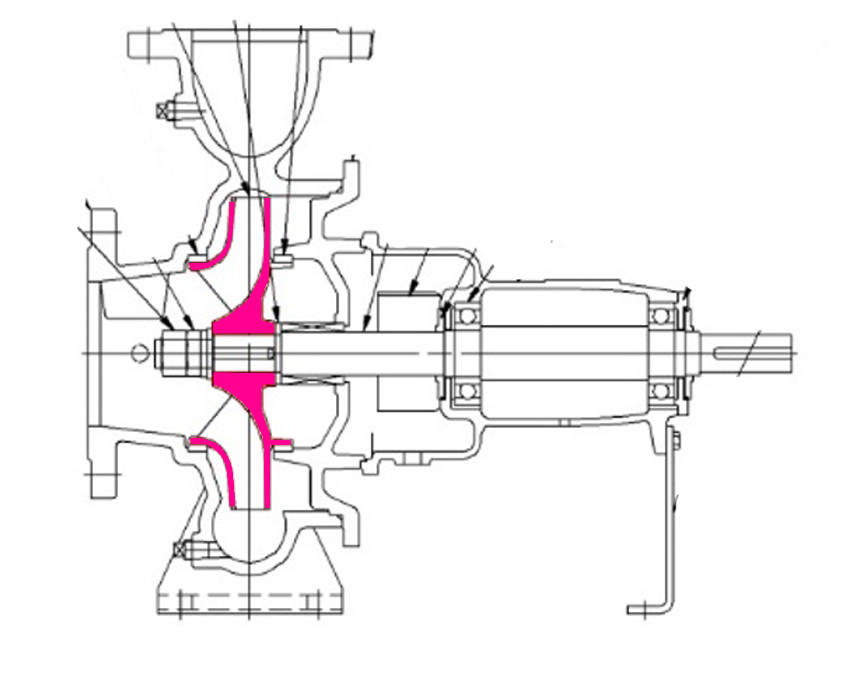

What is a Single-Stage Pump?

A single-stage pump has only one impeller, which means its pressure is generated in just one stage. This simpler design makes it ideal for applications that require low to moderate pressure, such as:

- Small irrigation systems

- Fluid transfer in light industries

- Firefighting systems

- Household applications

Because of its simpler construction, a single-stage pump is generally easier to maintain and has a lower initial cost. However, its pressure capabilities are limited, so it’s not suitable for applications that need high pressure.

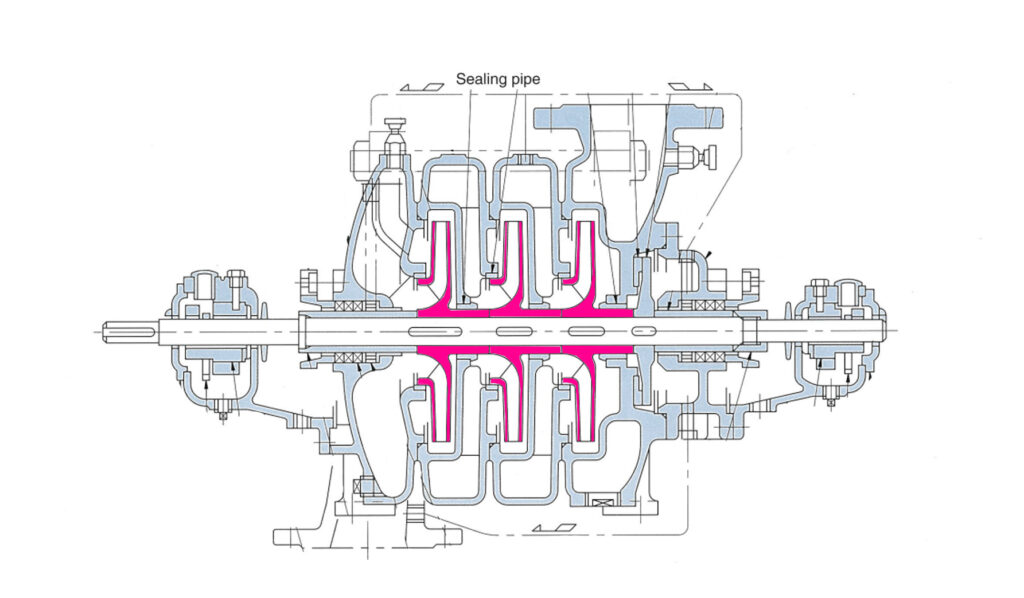

What is a Multistage Pump?

On the other hand, a multistage pump has more than one impeller, which are arranged in series. Each impeller increases the pressure from the previous stage, allowing this type of pump to generate much higher pressure. This makes multistage pumps ideal for applications like:

- Water supply for tall buildings

- Boiler systems

- Long-distance water distribution

- Large-scale irrigation systems

Although more efficient for high-pressure needs, multistage pumps usually have higher initial costs and maintenance requirements due to their more complex design.

Which One Should You Choose?

If your application requires low to moderate pressure and you want an economical solution that is easy to maintain, a single-stage pump may be the best choice. However, if you face high-pressure demands, such as supplying water to high-rise buildings or long-distance water distribution, a multistage pump is the better option.

Also, you can understand pump specifications here