Talking About Pumps? Basic Terms You Need to Know

Many People Know Pumps Move Water — But There’s More Behind It

Many people know that pumps are used to move water. However, in industrial applications, pumps involve many technical terms that are important to understand.

Therefore, this article discusses the basic terms in Basic Pump Theory (Definition of Terms) based on international industry standards such as Japanese Industrial Standards (JIS B 0131).

By understanding these terms, you will find it easier to read pump specifications, understand how pumps work, and choose the right pump for your needs.

What Is Basic Pump Theory?

Before diving into technical terms, it’s important to understand what Basic Pump Theory is.

In simple terms, this theory explains:

- How liquid is moved

- How pressure is generated

- How pump efficiency is calculated

In addition, this theory is a key reference in the design and use of industrial pumps.

1. Capacity (Discharge)

Capacity or Discharge is the volume of liquid that a pump can move within a certain time.

It is usually written in units such as:

- m³/min

- m³/s

In simple words, capacity shows how much liquid the pump can transfer.

The higher the value, the greater the amount of water that can be delivered.

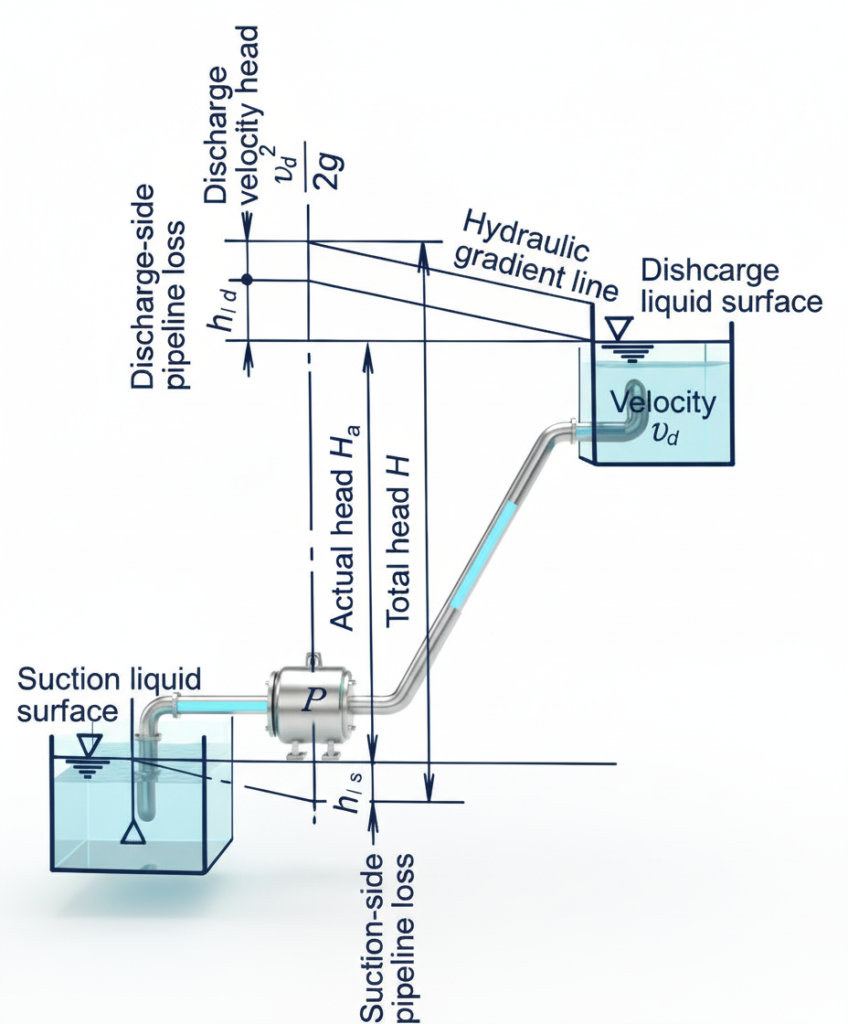

2. Total Head

Next, there is the term Total Head.

Total Head is the total force used by a pump to push liquid from one point to another.

In a pumping system, Total Head includes:

- Difference in water level (Actual Head)

- Losses in the suction pipe (Suction loss)

- Losses in the discharge pipe (Discharge loss)

- Flow velocity

Simply put, Total Head shows how strong the pump’s pushing power is.

3. Liquid Power

Then, there is the term Liquid Power.

Liquid Power is the real energy that the pump transfers to the liquid.

In other words, it is not just the electrical power going into the motor, but the actual energy used to move the liquid.

The higher the Liquid Power, the more energy the liquid receives.

4. Pump Efficiency

Next is Pump Efficiency.

Pump Efficiency shows how efficiently a pump works.

In simple terms, it is the comparison between:

- Useful energy

- Total energy supplied to the pump

If the efficiency is high, less energy is wasted.

As a result, pumps with high efficiency are more energy-efficient and cost-effective to operate.

5. Specific Speed (Ns)

Specific Speed is a number that shows the design characteristics of a pump.

This value helps determine:

- The most suitable pump type

- Pump performance characteristics

- The right application for the pump

In addition, Specific Speed is usually measured at the most efficient operating point.

Pump Working Principle Illustration

The illustration above shows the basic working principle of a pump system. Liquid enters through the suction side, is moved by the pump, and then pushed out through the discharge side. In this way, the pump helps transfer liquid steadily from one point to another.

6. Suction Specific Speed

Finally, there is Suction Specific Speed.

This term is used to determine how safely a pump operates on the suction side.

This value is closely related to the risk of cavitation, which is the formation of air bubbles that can damage internal pump components.

The better the value, the lower the risk of damage caused by cavitation.