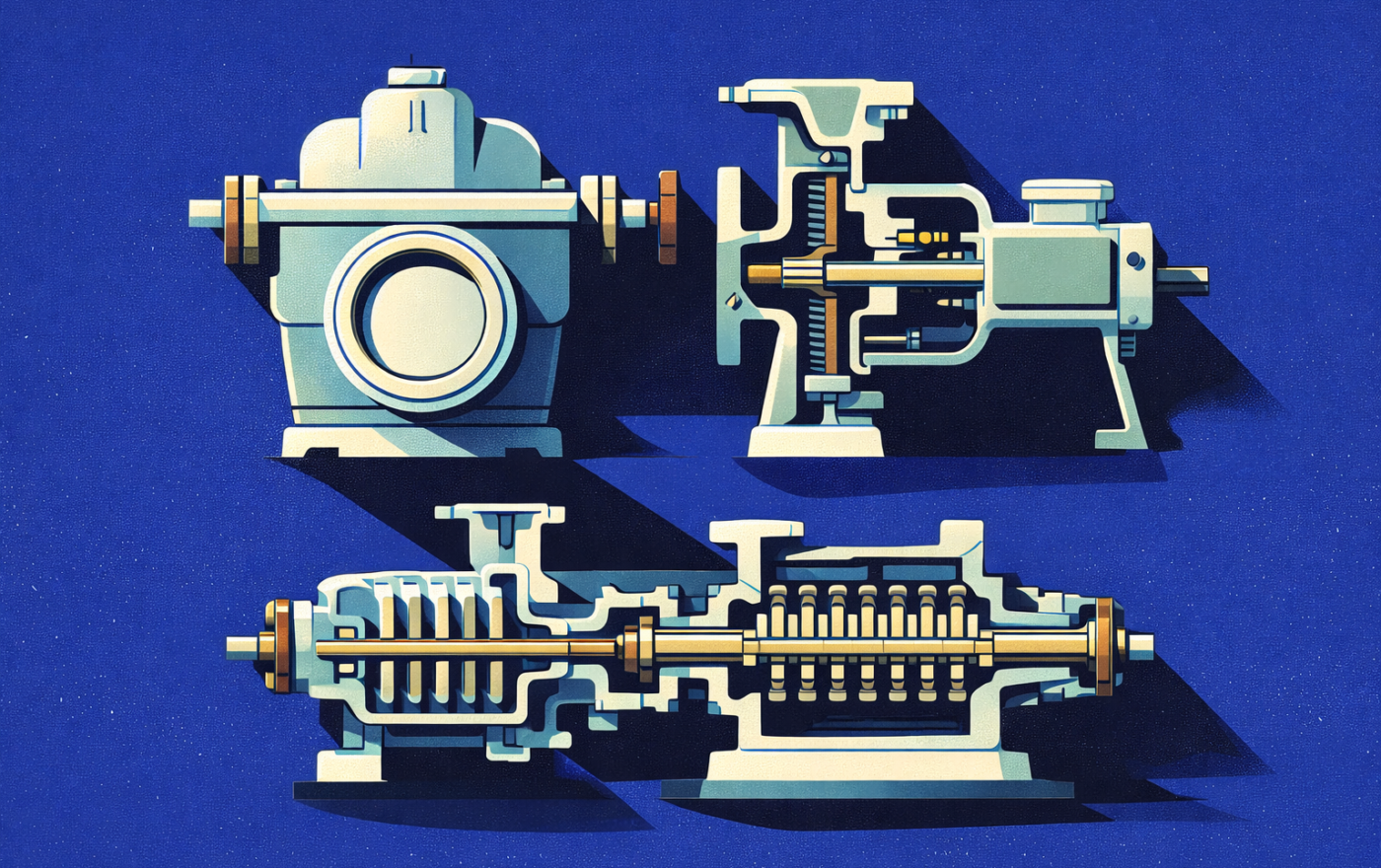

Split Casing Pump Construction: Types, Features, and Applications

Split Casing Construction is an important design concept in centrifugal pump technology, especially for applications requiring high flow rate, easy maintenance, and reliable operation. Based on casing construction, split casing pumps are divided into several types, each offering specific construction features and intended applications. Understanding these types helps engineers and end users select the most suitable pump for optimal performance and long-term operation.

Split Casing Construction

Split casing pumps are classified based on casing construction. Each type has specific construction features and applications, making it suitable for different operating conditions.

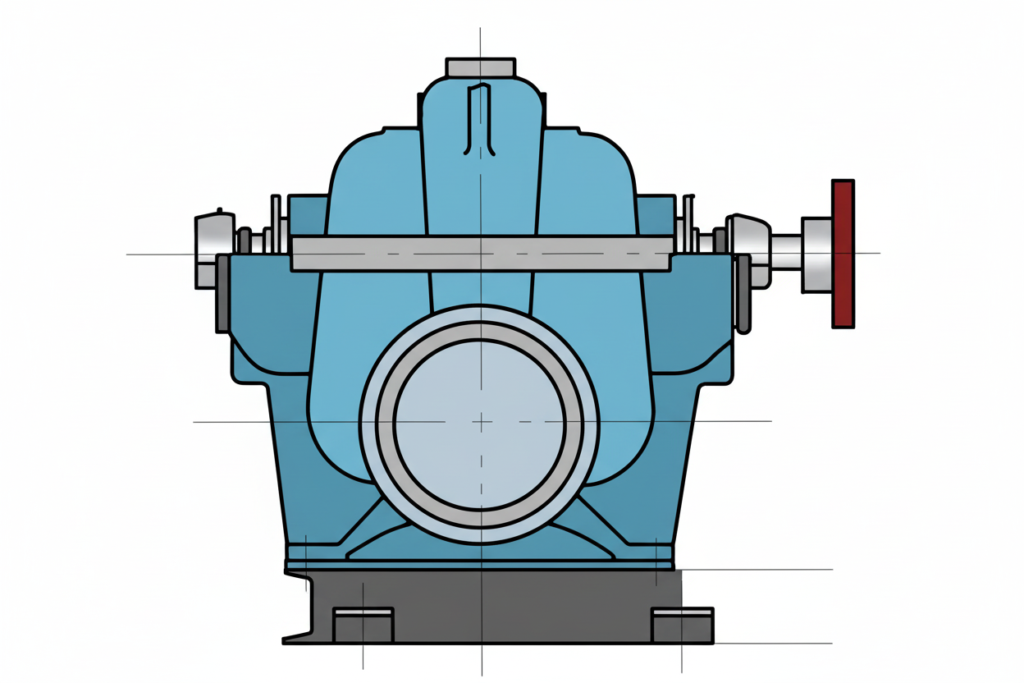

1. Horizontal Split Type

Construction Features:

- 2-piece split type at horizontal shaft

- Simple disassembly and inspection

- Rotating elements can be removed without moving driver

Applications:

- Mainly medium- and large-scale horizontal shaft pumps

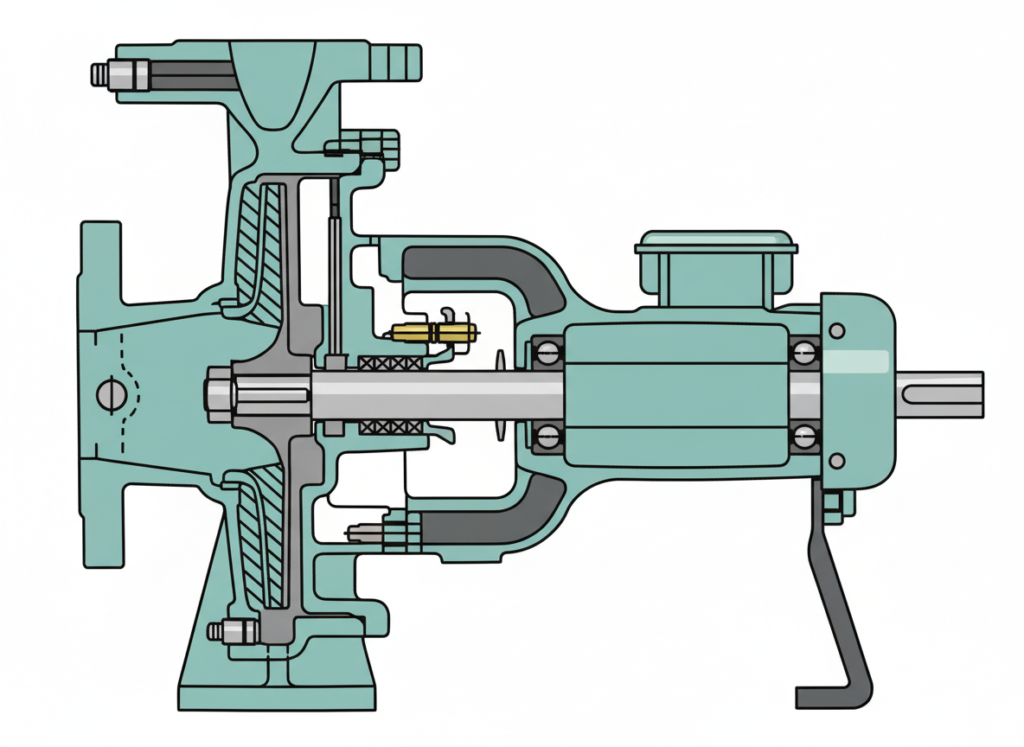

2. Radially Split Type

Construction Features:

- Impeller can be removed with casing in fixed position

Applications:

- Small- and medium-scale horizontal shaft pumps

- Large-scale vertical pumps

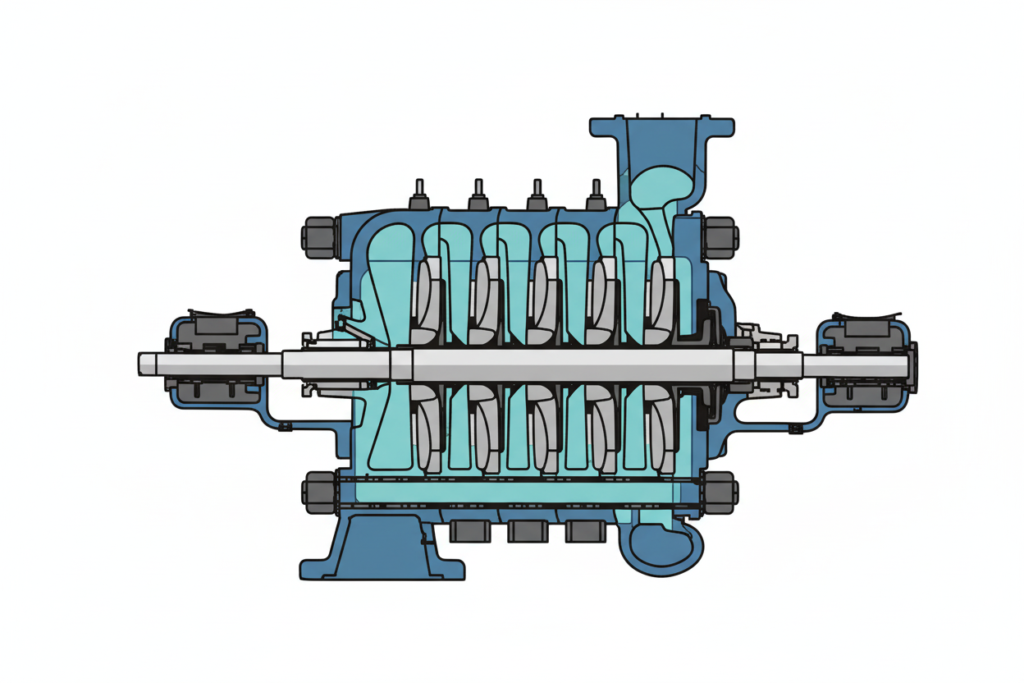

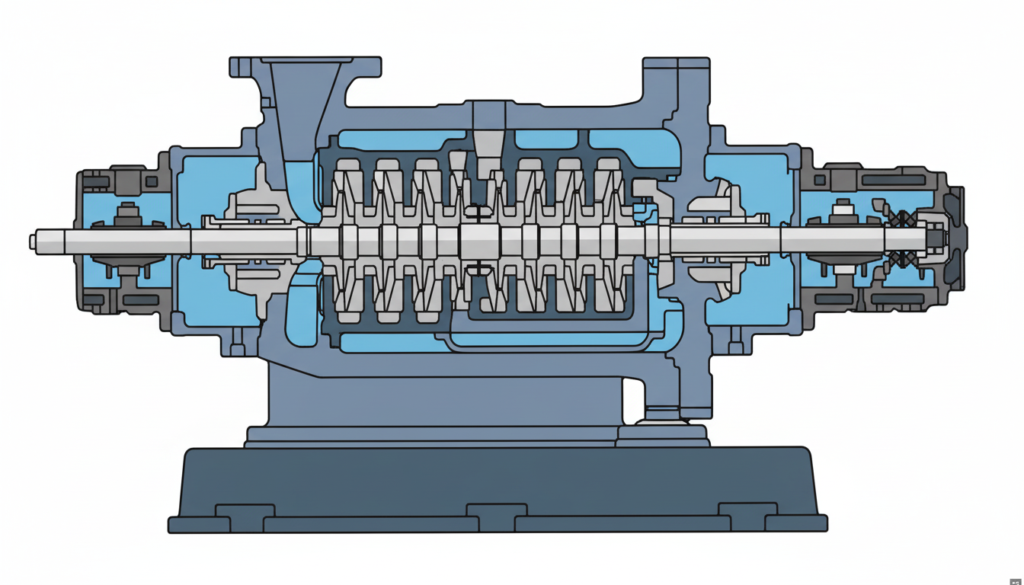

3. Multi-stage Sectional Type

Construction Features:

- Casing and impeller exist as a unit

- Number of stages is easily altered

Applications:

- Standard horizontal shaft multi-stage pumps

- Vertical shaft multi-stage mixed-flow pumps

4. Double Case Type

Construction Features:

- The outer of the two barrels has strength against internal pressure

Applications:

- Extra high-pressure pumps

- Dredger pumps, etc.