Jenis-Jenis Pompa dan Prinsip Kerjanya

Pumps have been used for centuries to move liquids in various applications. Each type of pump works differently and offers specific advantages. This article provides a clear overview of the main pump types based on their operating principles. The explanations follow the structure of the original technical content but use friendlier language to make it easier to understand.

Pump Types Based on Operating Principles

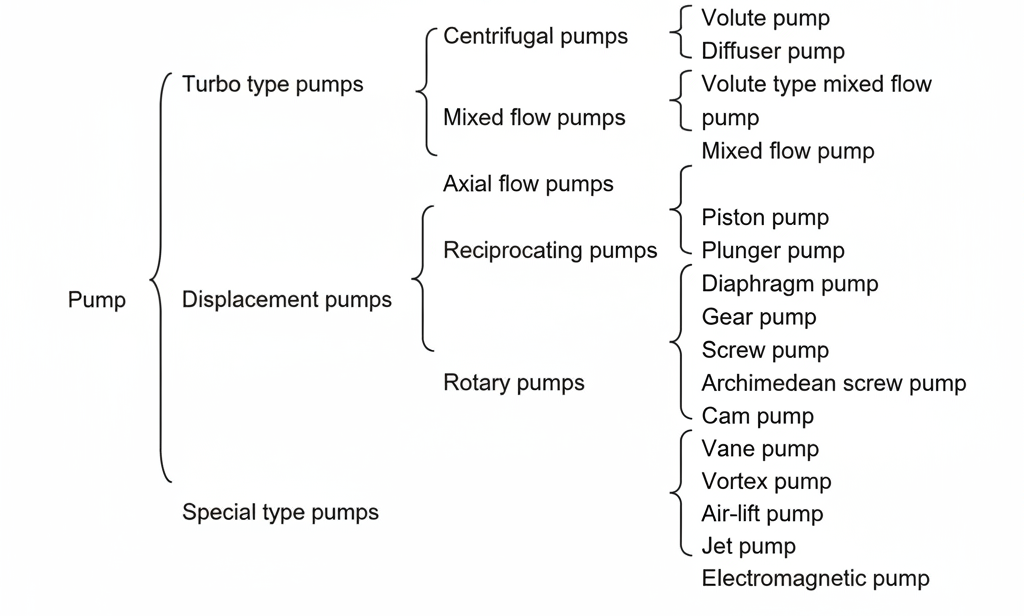

Many kinds of pumps have been used since ancient times. In general, pump types can be grouped into three major categories: turbo-type pumps, displacement pumps, and special-type pumps.

The following table shows pump types based on their operating principles.

Turbo-Type Pumps

Turbo-type pumps transfer energy to the liquid through a rotating impeller inside a casing. They deliver both pressure and velocity energy. This category includes three main types.

Centrifugal Pumps

Centrifugal pumps increase the liquid’s pressure and velocity through the centrifugal force of an impeller. Their specific speed (Ns) typically ranges from 100–700.

There are two main casing designs:

-

Volute pumps: convert velocity energy into pressure using a volute-shaped casing.

-

Diffuser pumps: use guide vanes to convert the liquid’s velocity energy into pressure more efficiently.

Mixed-Flow Pumps

Mixed-flow pumps generate pressure and velocity using both centrifugal force and the lifting force of impeller vanes. Their Ns values generally fall between 350–1,350.

Most units use diffuser vanes, but if a volute casing is used, the pump is called a volute mixed-flow pump.

Axial Flow Pumps

Axial flow pumps apply pressure and speed energy through the lifting force of vanes. Diffuser vanes then convert the speed energy into pressure. Their Ns value typically ranges from 1,000–2,500.

These pumps are ideal for large flow rates at relatively low heads.

Displacement Pumps

Displacement pumps move liquid using the pushing action of pistons, plungers, or rotating elements. Unlike turbo pumps, this type produces intermittent flow, which may cause pressure pulsations and vibration.

Displacement pumps fall into two groups.

Reciprocating Pumps

These pumps deliver liquid through the back-and-forth motion of pistons or related mechanisms. They are well-suited for high-pressure applications but produce pulsating flow.

Rotary Pumps

Rotary pumps move liquid using screws, gears, cam mechanisms, eccentric rotors, and similar rotating elements.

Common rotary pump types include:

- Gear pump

- Screw pump

- Vane pump

- Archimedean screw pump

- Cam pump

Rotary pumps provide a steadier flow than reciprocating pumps.

Special-Type Pumps

These pumps operate using principles different from both turbo-type and displacement-type pumps. Each design offers unique features for specific applications.

Examples include:

- Jet pump

- Air-lift pump

- Electromagnetic pump

These pumps are mainly used when traditional methods cannot meet the required performance.

Key Takeaways

- Turbo-type pumps include centrifugal, mixed-flow, and axial-flow designs.

- Displacement pumps include reciprocating and rotary types.

- Special-type pumps use unique mechanisms such as jet action, air lifting, or electromagnetic force.

Understanding the different pump types helps you choose the right equipment for specific applications. Each pump serves a particular purpose and offers benefits depending on the system requirements. Hopefully, this overview makes pump selection easier and clearer for your projects or engineering needs.