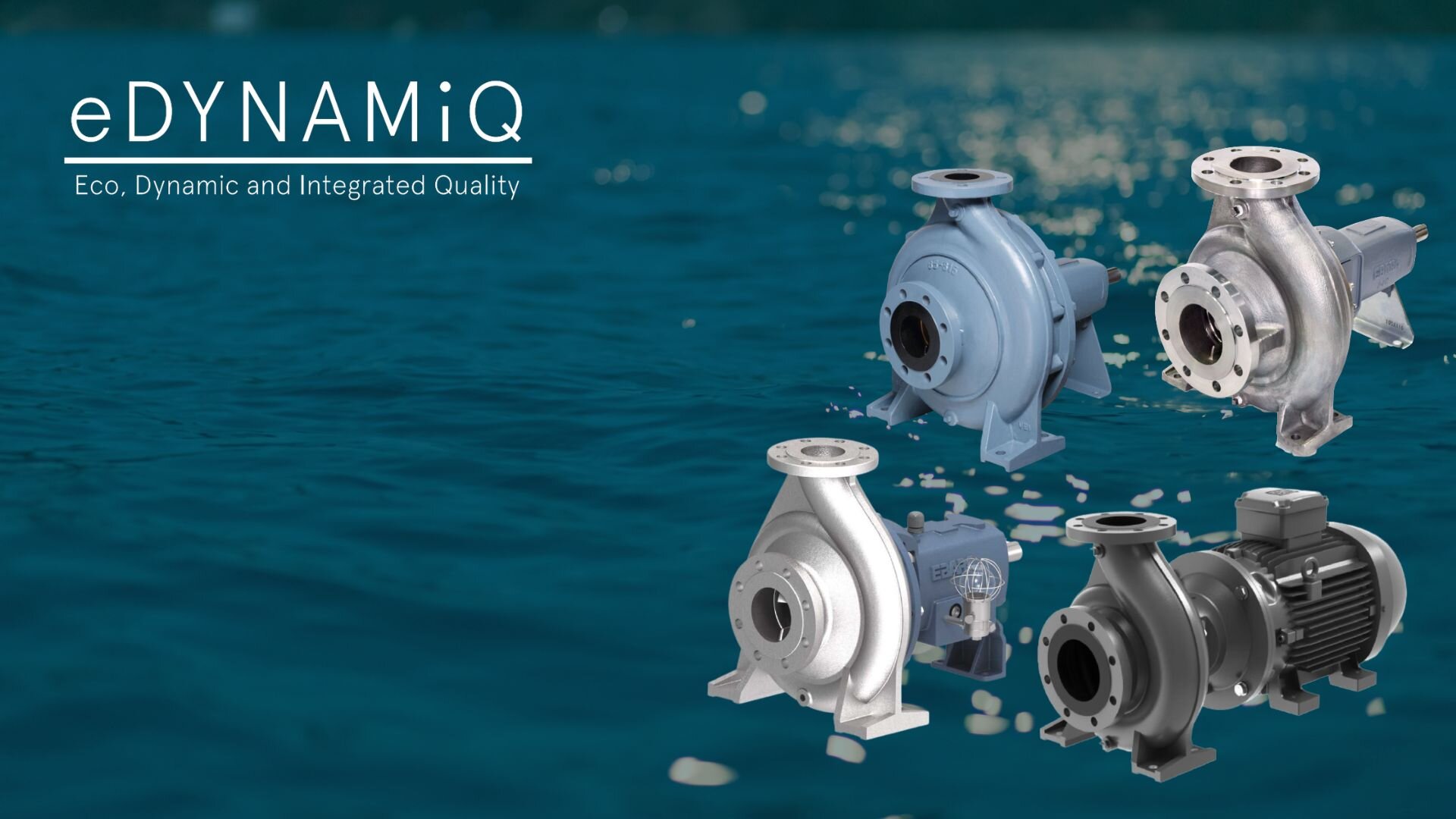

Japanese Technology, World Class Quality, For You

Looking ahead, going beyond expectations

Our Technology is to Build Your Trust!

We highly committed and professional to create high-quality products

See More

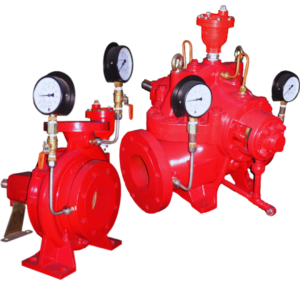

Ebara Fire Fighting Pump

Non Overload design to ensure stable performance for all applications

See More

Ready To Get Started On Your Project?

Fill out our online form with your specifications and requirements, get a detailed quote in accordance with your specific needs.

See More

Optimize Your Pump Performance

Request our pump assessment service and training program for the better performance.

See More

Scroll Down